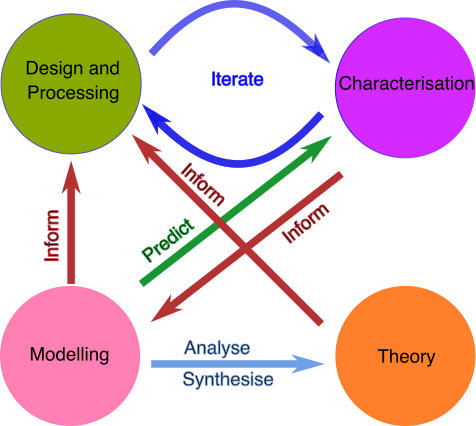

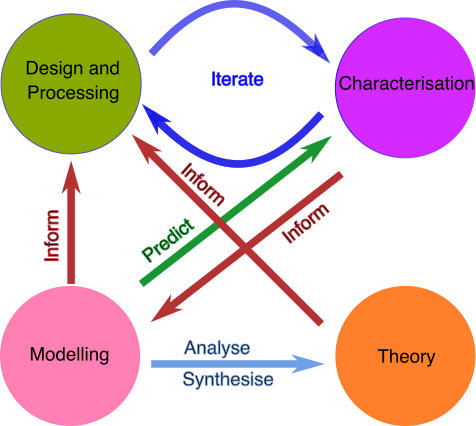

Flow Diagram of our Alloy Design Strategy

Written records of the quenching of steel exist as early as the first century of the European Iron Age. Archeological evidence for quenched and tempered steel exists from several centuries earlier. Tempering has been regarded as essential in order to mitigate the extreme hardness and brittleness of as-quenched steel. On the other hand the strength limit has been reached in low cost hardened martensitic and hard-drawn pearlitic steels.

We propose to push the envelope making the radical move of dispensing with the tempering step and designing new multiphase, as quenched, tough, lean (low cost, resource efficient) steel (MATLeS). The key is to exploit recently acquired understanding of the plasticity of body centered cubic metals; work hardening; and interplay between dissolved carbon, dislocations and metal carbonitrides. This will be put together with novel state-of-the-art experimental techniques: in particular precession electron microscopy and tensile stress relaxation. In powerful combination these will furnish us with the means to manipulate and exploit the hierarchical lath martensite microstructure (HiLaMM). The new steels we design will have excellent green credentials: resource efficiency, recyclability, high strength-to-weight ratio. Our vision is toward the electric vehicle economy, light-weighting of structural offshore wind farm components and super-strong cables for undersea and civil engineering projects. Making full-circle, our outcomes will inform modern theories in materials science, advancing solutions to one of the world's outstanding scientific questions: what is the nature of work hardening? (Why can I not straighten the poker you have just bent?)

Flow Diagram of our Alloy Design Strategy